- Fragen & Antworten

- Mein Konto

- Newsletter

- Kontakt

- Redaktion: +49 2203 3584 0

- Abo-Service: +49 40 23670 300

- Mein Konto

- Logout

In this paper, novel burning configuration is applied to combustion equipment for steel industry. The new set up allows hydrogen and methane blend experiments at industrial scale for powering GF-ELTI furnaces (H2 content up to 100% v).

This paper was published in issue 1–2/22 of stahl + eisen. Authors are L. Ghirardelli, M. Teani, D. Macario; GF-ELTI.

Hydrogen seems a promising technology for the energy transition thanks to its carbon free combustion emission. Despite having similar tendencies to methane, hydrogen properties are significantly different. These gases possess common features like being lighter than air, colourless, odourless, tasteless, causing asphyxias even if non-toxic and flammable. When comparing the two fluids at gaseous state, hydrogen density is eight times lighter than methane. It means that hydrogen is extremely leakage prone and difficult to handle and to confine. Hydrogen leakages may happen inside pipelines when some sort of material degradation occurs (i.e. embrittlement). Losses of hydrogen into atmosphere are not desired as they affect climate tremendously [1,2,6].

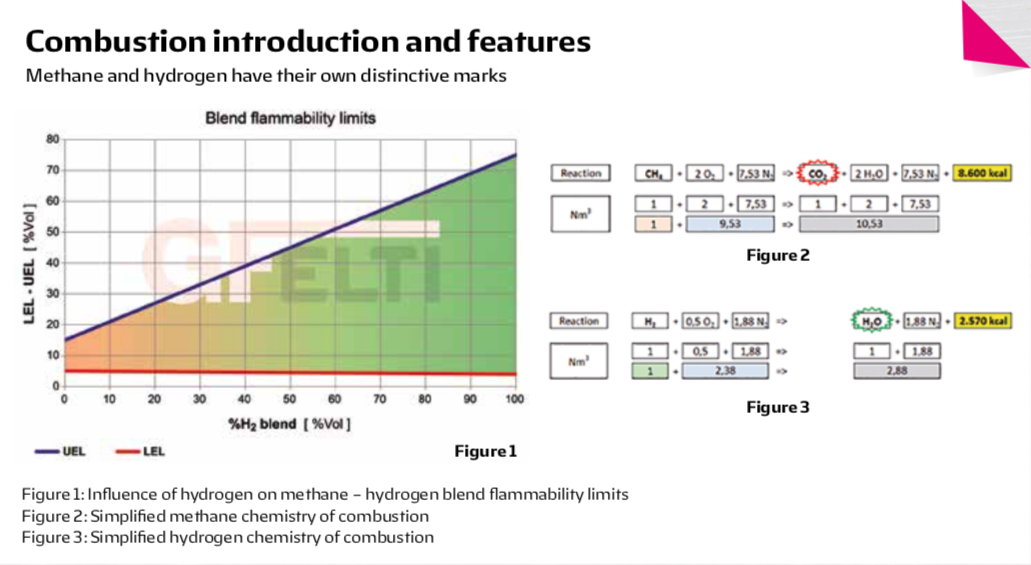

Extremely low density influences hydrogen lower heating value per unit mass which is 2,4 times greater than methane (119,9 MJ/kg against 50,2 MJ/ kg). That is why hydrogen is recognised as energy carrier [2]. On the other hand hydrogen lower heating value per unit volume is only one third methane’s (2.570 kcal/Nm3 against 8.600 kcal/ Nm3).

This feature impacts onto combustion flow rates. The amount of hydrogen necessary to provide equal methane thermal output is 3,35 times greater.

Speaking of combustion, it is necessary to make some consideration on flammability and flame characteristics. Hydrogen requires little injection energy to be activated: only 0,02 mJ whilst methane 0,29 mJ. Hazards on this topic are consequently a major concern [3-4].

The experiments carried out with H2Burn project lead to relevant changes in hydromethane blend flammability levels. Increasing content of hydrogen means having a consistent enlargement of blend flammability levels. These figures are illustrated in Figure 1. Virtually, hydrogen combustion by product is water. Compared to methane that generates almost 2 kg of CO2 per each Nm3, hydrogen generates 0,8 kg of water per Nm3.

A simplified methane and hydrogen stoichiometric reaction is presented in Figure 2 and Figure 3. Stoichiometry dictates air to fuel ratio to enable combustion. Methane ratio is 9,53:1, generally speaking 10:1. It means that 10 Nm3 of air are necessary to completely burn 1 Nm3 of methane. Likewise, hydrogen ratio is 2,38:1; in practice 2,5:1. It is evident that hydrogen combustion benefits a little reduction in air flowrate.

Hydrogen requires specific skills to be handled safely. It is mandatory to have awareness of its properties. In order to be ready, GF-ELTI decided to attend courses on Hydrogen safety and hazards held by Professor Marco Nicola Carcassi – President of International Conference of Hydrogen Safety (ICHS). GF-ELTI could benefit also from previous experiences of industrial equipment supply, such as ladle and tundish heaters, furnaces for the agglomeration process, as well as reheating furnaces for continuous production. These applications are feeded by coke gas, which has hydrogen content up to 60%v [5-6].

After training completion, H2Burn project started officially. Firstly, the engineering of new burning apparatus capable of performing with methane, mixtures of methane and hydrogen and pure hydrogen (100%v). Then, it was necessary to develop a device that could generate the desired hydrogen volumetric percentages in real time. This remotely-controlled solution called Fluids Dynamic Blending Unit (i.e. FDBU). This is the beating heart of H2Burn technology.

The installation of this equipment is done onto two industrial furnaces at GF-ELTI heat treatment division in Sovere, Bergamo. This facility is where R&D projects take place. The division has twenty furnaces 1 – 150 t charge and 50.000 t per year production capacity. All the installations are equipped with state-of-the-art high-efficiency GF-ELTI burners. Recuperative furnace C40 and regenerative furnace C47 are selected for the test. Both furnaces operate with the principle of combustion air pre-heating.

Erhalten Sie exklusiven Zugriff auf alle Fachartikel, Whitepaper und Analysen.